Applications

Applications

Our organisation categorises electrical components based on specific purposes and voltage criteria, simplifying their selection for diverse applications.

What is EMS

What is EMS

An Energy Management System (EMS) in the electrical industry refers to a system of computer-aided tools used by operators of electric utility grids to monitor, control, and optimize the performance of the generation and/or transmission system. The scope of an EMS can also extend to distribution networks and industrial applications, focusing on energy efficiency and optimization within a facility or organization.

Necessity of Energy Management System

Necessity of Energy Management System

The necessity of an Energy Management System (EMS) in an industry is driven by several critical factors that impact both operational efficiency and financial performance. Industrial operations typically consume a significant amount of energy, making energy management a key area for cost savings and sustainability efforts. Here are the main reasons why an EMS is essential in an industrial context:

Energy is often one of the largest operational expenses in industrial operations. An EMS helps in identifying and implementing energy-saving measures, significantly reducing energy costs.

It allows for the optimal use of energy resources, ensuring that energy is consumed efficiently across various processes and systems within the industry.

Industries face increasing pressure to comply with environmental regulations, including those related to energy consumption and greenhouse gas emissions. An EMS helps in monitoring, reporting, and reducing emissions, facilitating compliance with these regulations.

Many companies are committed to sustainability goals that include reducing their carbon footprint and environmental impact. An EMS is crucial for achieving these goals by enabling more sustainable energy management practices.

By ensuring that energy systems are operating efficiently, an EMS can reduce the risk of equipment failure and downtime, enhancing overall operational reliability and performance.

Effective energy management helps in reducing dependency on external energy sources and mitigating risks related to energy supply disruptions.

Companies that implement robust energy management practices can achieve a competitive advantage through reduced operating costs, improved sustainability credentials, and compliance with regulatory standards.

An EMS provides valuable data and insights into energy usage patterns and inefficiencies. This information supports informed decision-making regarding energy investments, operational adjustments, and long-term planning.

Industries can respond more effectively to changes in energy prices and market demands by adjusting their energy consumption and production processes in real time.

For industries looking to integrate renewable energy sources into their operations, an EMS is essential for managing the variability and ensuring the efficient use of these resources.

In summary, the necessity of an Energy Management System in an industry is multifaceted, addressing economic, environmental, operational, and strategic needs. An EMS not only helps in cutting costs and meeting regulatory requirements but also supports broader sustainability objectives, operational excellence, and the resilience of industrial operations.

Who needs EMS?

Who needs EMS?

Energy Management Systems (EMS) are crucial for a wide range of entities and sectors. They are particularly important for organizations where energy usage is significant, costs are high, and there is a need to monitor and control energy for operational and environmental reasons. Here are the primary groups and sectors that typically require an EMS:

Manufacturing plants, refineries, and processing facilities where energy consumption is a major part of operational costs. EMS helps optimize energy usage in machines, processes, and assembly lines.

This includes office buildings, shopping centers, hotels, and hospitals. These entities use EMS to manage HVAC (heating, ventilation, and air conditioning) systems, lighting, and other energy-consuming assets to reduce costs and enhance comfort.

Power generation companies and grid operators utilize advanced EMS for the generation, transmission, and distribution of power to ensure grid stability, integrate renewable energy sources, and meet regulatory requirements.

Schools, universities, government buildings, and public lighting systems need EMS to manage their energy costs, comply with sustainability goals, and demonstrate public leadership in energy efficiency.

With their high power usage for servers and cooling systems, data centers benefit greatly from EMS to reduce energy consumption while maintaining the necessary environment for optimal equipment operation.

Includes airports, railway stations, and ports where EMS can manage the large and varied energy use efficiently, from lighting and heating to the operation of various transport-related equipment.

High-rise residential buildings and housing complexes use EMS to monitor and control heating, cooling, and communal energy services, improving energy efficiency and reducing collective energy costs.

Wind farms, solar parks, and hydroelectric plants use specialized EMS to optimize the production of energy and its integration into the power grid.

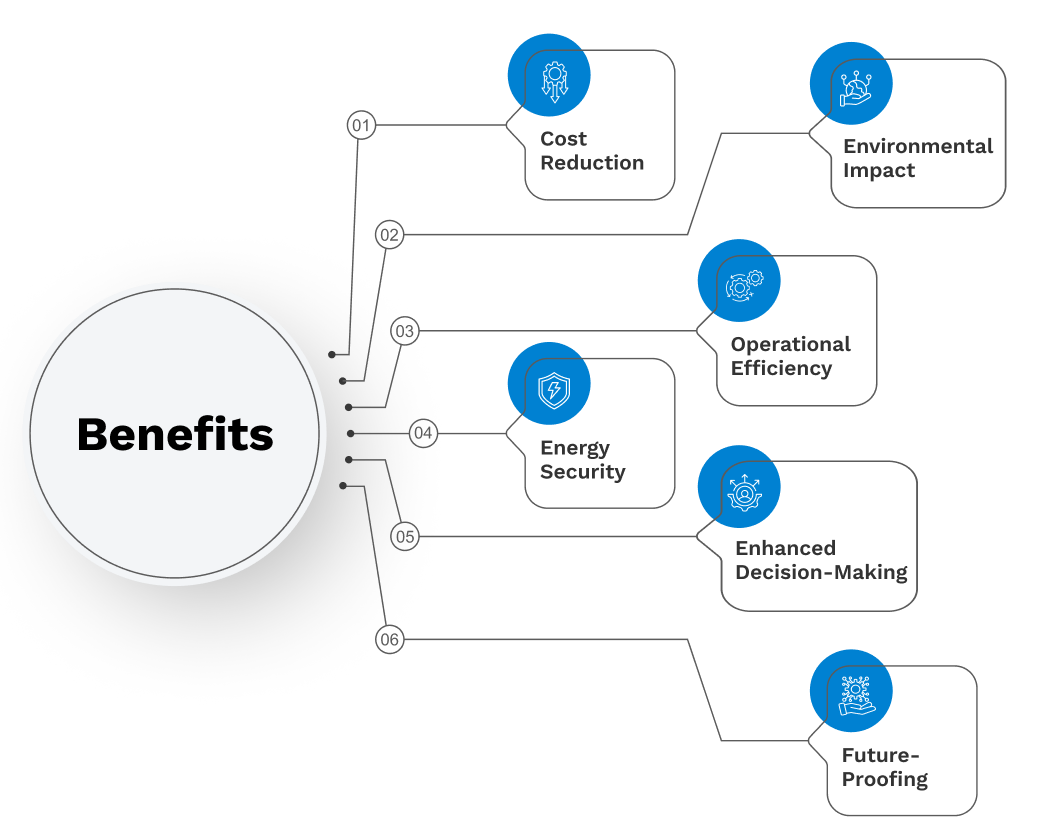

Benefits of having an Energy Management System

Benefits of having an Energy Management System

What is the detailed scope of work involved in EMS

What is the detailed scope of work involved in EMS

The scope of work involved in implementing an Energy Management System (EMS) can be quite extensive and varies depending on the specific needs and scale of the operation. Here’s a detailed breakdown of typical tasks and components involved: