Applications

Applications

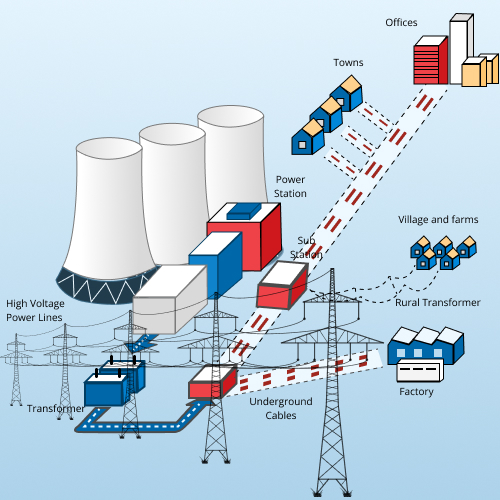

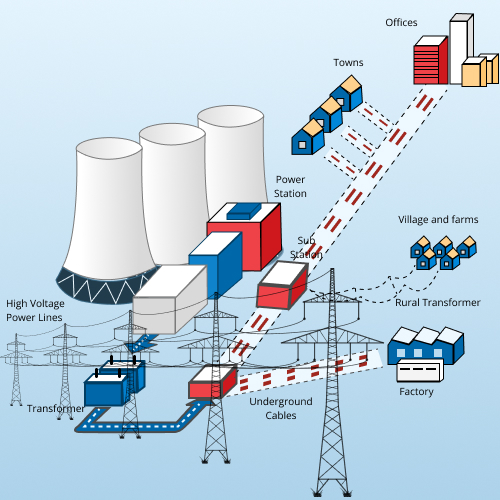

Our organisation categorises electrical components based on specific purposes and voltage criteria, simplifying their selection for diverse applications.

Services

Services

Our specialised electrical solutions deliver end-to-end maintenance support, ensuring consistent stability, safety, and reliability across diverse industries. By proactively addressing risks and performance gaps, we help minimise operational uncertainties and enable smooth, uninterrupted processes

Arc Flash Study is a crucial component of electrical safety in an industrial workplace. It helps safeguarding personnel, comply with regulations, assess and mitigate risks, and ultimately minimize the potential for catastrophic electrical accidents and their associated consequences. We will strictly follow the guidelines specified by NFPA-70E and IEEE-1584 while conducting study at site by using power system tool like ETAP. Prioritizing electrical safety through this study is not only a legal requirement but also a moral and ethical imperative for organizations committed to the well-being of their employees. If you are aiming to protect your employees, contact us by sending an email to reach@lselectricals.com or by filling the enquiry form.

Critical components of power systems, current transformers (CTs) and potential transformers (PTs) convert and measure high voltage and current levels into values that protective relays, meters, and other instruments can safely process. It contributes to the longevity of the transformers, aids in the prevention of operational issues, and ensures adherence to industry regulations and standards. Therefore, consistent maintenance and testing procedures enhance the overall dependability and effectiveness of power systems. For inquiries regarding the protection of your electrical system, please contact us via the inquiry form or by sending an email to reach@lselectricals.com.

Earth pit testing is a necessity in various industries and electrical installations to ensure safety, protect personnel and equipment, maintain operational continuity, prevent fires, comply with regulations, provide lightning protection, reduce Electromagnetic Interference(EMI), optimize electrical performance, plan maintenance activities, and protect the environment. It is a fundamental practice for maintaining the reliability and safety of electrical systems. If you are looking to safeguard your electrical system, contact us by sending an email to reach@lselectricals.com or by filling the enquiry form

An Electrical Safety Audit (ESA) is essential for ensuring the safety, reliability, and efficiency of electrical systems while complying with statutory and international standards. It identifies hidden risks such as overheating, faulty earthing, overloading, and energy losses that can lead to fires, shocks, equipment failure, and downtime. Through systematic inspections, diagnostic testing, and risk assessment, an ESA improves power quality, enhances system performance, extends equipment life, and reduces operational costs. Required for industries, hospitals, commercial buildings, data centres, and all energy-dependent facilities. If you are looking to enhance electrical safety, ensure compliance, and improve system reliability, contact us by emailing reach@lselectricals.com or by filling out the enquiry form.

An Energy Audit is a systematic evaluation of how energy is consumed, distributed, and wasted within a facility, helping organisations improve efficiency, reduce costs, and meet regulatory and sustainability goals. It analyses electrical, thermal, and fuel usage to identify inefficiencies such as energy losses, poor power factor, oversized equipment, and idle running. Supported by cost–benefit analysis, an energy audit provides practical recommendations, a clear savings roadmap, and a baseline for continuous improvement aligned with standards like ISO 50001 and BEE guidelines. Suitable for industries, commercial buildings, utilities, and institutions, it strengthens operational reliability while lowering environmental impact.

If you are looking to reduce energy costs and improve efficiency, contact us by emailing reach@lselectricals.com or by filling out the enquiry form.

Energy Management System is a crucial tool for organizations looking to optimize their energy use, reduce costs, enhance sustainability, and meet environmental goals. It provides the data, insights, and automation necessary to make informed decisions and take proactive measures to improve energy efficiency and resource management. As energy resources become scarcer and environmental concerns grow, adopting an EMS is not only a strategic advantage but also a responsible and forward-thinking approach to managing energy resources efficiently. If you are looking for financial savings and reduce the carbon footprints, contact us by sending an email to reach@lselectricals.com or by filling the enquiry form.

Energy Meter Testing plays a critical role in maintaining fair and transparent billing, protecting revenue, building consumer trust, supporting energy efficiency efforts, complying with regulations, and ensuring the safe and reliable operation of electrical systems. Regular testing and calibration of energy meters are essential to address these critical concerns and maintain the integrity of the electricity distribution system. Accurate meter data is the fundamental for the efficient and effective operation of electrical utilities. Are you looking for testing and calibration of energy meters, contact us by sending an email to reach@lselectricals.com or by filling the enquiry form.

A study that is crucial to understanding electrical system design and maintenance because it reduces harmonic distortion and ensures power distribution networks operate dependably and efficiently. It assists in figuring out the levels of harmonic disturbance, the need for filtering inside a facility, and whether or not harmonic voltages and currents meet IEEE519-2014 standards for acceptable levels.A specialized and committed staff from L S Electricals will do studies at your plant using Power Analyzer or ETAP simulations upon request. Please fill out the enquiry form or send an email to reach@lselectricals.com if you would like further information regarding the health of your system.

Breaker servicing in an electrical system is a critical maintenance practice to ensure safety, reliability, and preventive maintenance, compliance with regulations, downtime reduction, fire prevention, equipment protection, operational continuity, energy efficiency, data-driven decision-making, environmental protection, and safety during fault conditions. It contributes to cost savings, equipment longevity, and operational continuity and is in various industries and applications. If you are looking for an uninterrupted electrical system, contact us by sending an email to reach@lselectricals.com or by filling the enquiry form.

Relay coordination is necessary to ensure the safe, reliable, and efficient operation of electrical power systems. It plays a central role in isolating faults, protecting equipment, maintaining system stability, complying with regulations, minimizing downtime, and safeguarding both the electrical infrastructure and personnel. Effective relay coordination contributes to the overall resilience and robustness of the electrical grid. Proper coordination leads to efficient maintenance practices, improved energy efficiency, cost savings, and uninterrupted industrial operations. If you are looking for effective relay coordination, contact us by sending an email to reach@lselectricals.com or by filling the enquiry form

Relay testing is essential in an industrial electrical system to ensure equipment protection, personnel safety, downtime reduction, preventive maintenance, quality assurance, regulatory compliance, optimal system performance, data-driven decision-making, energy efficiency, asset management, operational continuity, and cost savings. It is a critical component of industrial maintenance and safety protocols, contributing to the overall reliability and efficiency of industrial operations.If you want to protect your electrical system, contact us by sending an email to reach@lselectricals.com or by filling the enquiry form.

Elevate your electrical power systems with LS Electricals' imperative retrofitting solutions. Designed to accommodate technological advancements, ensure regulatory compliance, and optimise system efficiency, our approach mitigates obsolescence with minimal disruption. Explore retrofitting applications for

A Remaining Useful Life (RUL) Study is a scientific assessment that determines how long critical electrical assets such as transformers, motors, and power cables can continue to operate safely, reliably, and economically before failure risk becomes unacceptable. By combining advanced field diagnostics, condition monitoring data, degradation models, and standards-based Health Index scoring, the study identifies hidden defects, dominant aging mechanisms, and time-to-failure. It enables condition-based maintenance, prevents unplanned outages, improves safety, optimises CAPEX/OPEX, and extends asset life while ensuring compliance with relevant IEC, IEEE, IS, and safety standards.

If you are looking to assess asset health and plan reliable, data-driven maintenance, contact us by emailing reach@lselectricals.com or by filling out the enquiry form.

Its primary function is early fault detection, essential for preventing costly breakdowns and downtime. By enabling preventive maintenance, it maintains equipment condition and operational continuity. Additionally, thermography enhances safety, supports energy efficiency, and ensures product quality. It contributes to environmental sustainability and equipment reliability through its non-invasive nature. Our services offer essential documentation and aid in regulatory compliance, making thermography an indispensable asset for optimizing efficiency and safety in industrial operations.

Periodic filtration of transformer oil is of utmost importance in order to ensure the efficient operation and upkeep of transformers, especially in settings characterized by high electrical demand or severe operational circumstances. By implementing this procedure, transformers not only experience an increase in operational efficiency but also substantial improvements in safety and dependability.