Applications

Applications

Our organisation categorises electrical components based on specific purposes and voltage criteria, simplifying their selection for diverse applications.

Arc Flash Study

Arc Flash Study

An arc flash study is an engineered incident energy analysis defined to establish safety protocol for qualified electrical personnel required to work on electrical equipment and circuit parts that cannot be placed in an electrically safe work condition.

Protocol such as proper levels of PPE based on both the shock and arc flash boundaries are defined by the calculated incident energy. Other benefits of an engineered arc flash study include a short circuit & coordination study and updated facility electrical documentation including one-line diagrams and electrical equipment locations.

What is an Arc Flash?

What is an Arc Flash?

An arc flash is an electrical explosion that is triggered by an electrical arc. An arc is a release of energy that travels through the air between conductors or between a conductor and the ground. An arc flash can be violent and dangerous and may produce sound waves, extreme temperatures that exceed 35,000째F, intense light, or an arc blast. The resulting thermal energy can be dissipated as radiant, conductive, or convective heat which can result in burns, blindness, hearing loss, collapsed lungs, and in extreme cases, death.

Causes

Causes

There are various reasons that can lead to an arc flash, such as:

Issues with insulation, incorrect installation, or previously damaged equipment can cause short circuits that result in an arc flash.

Unintentional contact with live components, dropping tools or other conductive materials onto electrical parts, or improper operation of equipment can trigger an arc.

Dirt, rust, or water can weaken insulation and conductive paths, making it easier for an electrical arc to occur.

Testing, repairs, and installations can generate arcs if done without precautions or without understanding the system's status.

Unexpected increases in voltage, caused by external elements such as lightning strikes or power surges, may surpass the insulation's capacity, resulting in an arc.

Using equipment beyond its recommended capacity or in a way not intended by the manufacturer can lead to overheating and arcing.

Where do Arc Flash hazards occur?

Where do Arc Flash hazards occur?

Arc flash dangers may arise in an electrical system at various locations where electrical energy is utilized, altered, regulated, or transferred. Here are some examples:

These components help to distribute power within a facility and may pose arc flash hazards during operation, maintenance, or fault conditions.

Transformers regulate voltage levels between various circuits, and any malfunctions or short circuits can result in arc flashes.

MCCs are used to control the operation of electric motors. The high current used by motors and the switching actions within MCCs can create arc flash hazards.

Any confined area with electrical components, such as control panels, may pose arc flash risks, particularly if they are accessed for inspection or maintenance while still powered.

These devices are designed to interrupt current flow, but their operation, especially under load or fault conditions, can cause arc flashes.

These parts are responsible for transferring significant amounts of electrical power to different sections of a system. Issues like loose connections, corrosion, or overloading can result in arc flash incidents.

Locations where cables are connected or terminated, such as junction boxes, can be prone to arc flashes if there are faults, damage, or improper installations.

In locations such as data centers, PDUs are responsible for distributing power to IT equipment. Overloads or short circuits in this situation can lead to arc flashes.

Why Arc Flash Hazard Study?

Why Arc Flash Hazard Study?

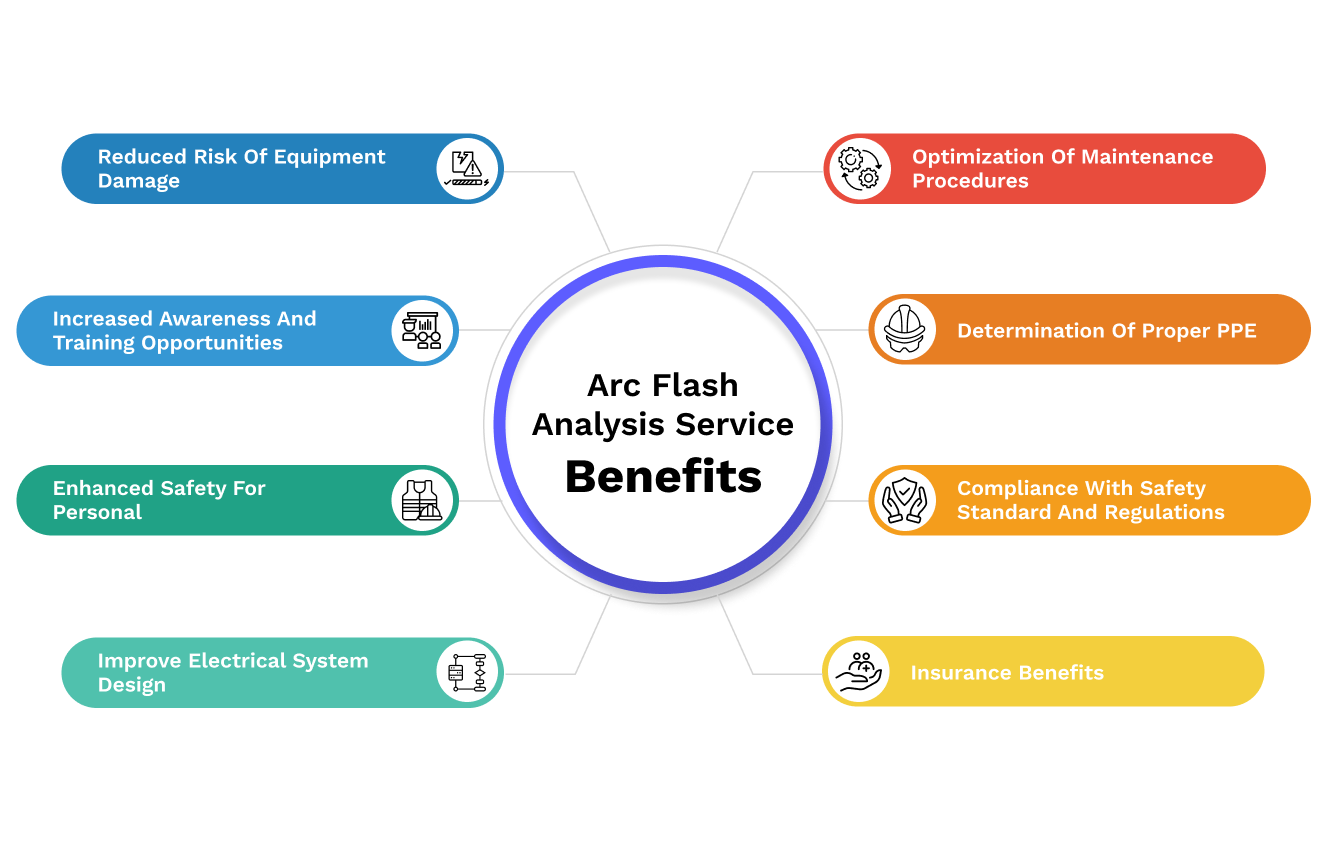

Conducting an Arc Flash Study in an electrical system is crucial for a variety of reasons. Here are a few listed below.

Ensuring the safety of personnel who work on or near electrical equipment is the primary purpose of conducting an arc flash hazard study. Arc flash incidents have the potential to cause serious injuries or even fatalities because of the extreme heat, light, and pressure blast they generate. Recognizing possible dangers enables the establishment of safety precautions to safeguard workers.

Employers must evaluate the workplace for electrical hazards and implement necessary safety measures to comply with safety standards and regulations like the National Fire Protection Association (NFPA) 70E. Conducting an arc flash hazard study is essential for meeting regulations and preventing potential legal and financial consequences.

The study offers comprehensive insights into the arc flash energy levels at various locations within the electrical system. This data helps in identifying the right category of PPE needed for workers, guaranteeing they are properly shielded from the particular risks they might face.

Examining arc flash dangers can reveal vulnerabilities in the electrical system's design or operation. This can result in enhancements to the electrical distribution system, including improved coordination of protective devices to reduce arc flash energy levels and enhance system reliability.

Arc flash incidents have the potential to result in extensive harm to electrical equipment, resulting in expensive repairs and operational interruptions. Identifying potential hazards allows for taking measures to decrease the chances of arc flashes, which safeguards the equipment and minimizes operational disruptions.

Discoveries from an arc flash investigation can help create specific training initiatives for staff, enhancing their understanding of potential dangers and safe work practices. This information contributes to promoting a culture of safety within the organization.

By conducting the study, facilities can discover ways to decrease workers' exposure to incident energy. This can be achieved by modifying protective device settings or redesigning parts of the electrical system to lower fault currents and arc flash energies.

Who Needs an Arc Flash Study

Who Needs an Arc Flash Study

Arc flash dangers may arise in an electrical system at various locations where electrical energy is utilized, altered, regulated, or transferred. Here are some examples:

Manufacturing plants, processing plants, and other industrial settings with substantial electrical infrastructure require arc flash studies to protect workers and equipment.

Office buildings, shopping malls, hospitals, and schools, especially those with significant electrical loads and systems, need these studies to ensure the safety of occupants and maintenance personnel.

Companies that generate, transmit, or distribute electricity must conduct arc flash studies to safeguard their employees and ensure the reliability of the power grid.

Due to their critical operational nature and the high electrical demand, data centers require arc flash studies to prevent downtime and protect personnel.

During the construction or renovation of buildings and facilities with significant electrical systems, arc flash studies are needed to guide safe construction practices.

Firms involved in the design, maintenance, or upgrade of electrical systems must perform arc flash studies as part of their service offerings to ensure the safety and compliance of their designs.

When is an Arc Flash Study Needed?

When is an Arc Flash Study Needed?

Conducting an Arc Flash Study in an electrical system is crucial for a variety of reasons. Here are a few listed below.

Before constructing or renovating facilities, to incorporate safety measures into the design of the electrical system.

Whenever there are major changes to the electrical distribution system or the load, which could affect the arc flash hazard levels.

To meet the requirements of safety standards (like NFPA 70E) that mandate risk assessments for electrical hazards.

Even if there haven't been significant changes, it's recommended to conduct arc flash studies periodically (every 3 to 5 years is a common recommendation) to account for any minor changes and ensure ongoing compliance and safety.

Following an incident or near miss involving electrical equipment, to analyze what happened and prevent future occurrences.

To evaluate how the addition affects the overall system's arc flash hazard levels and to update safety protocols accordingly.

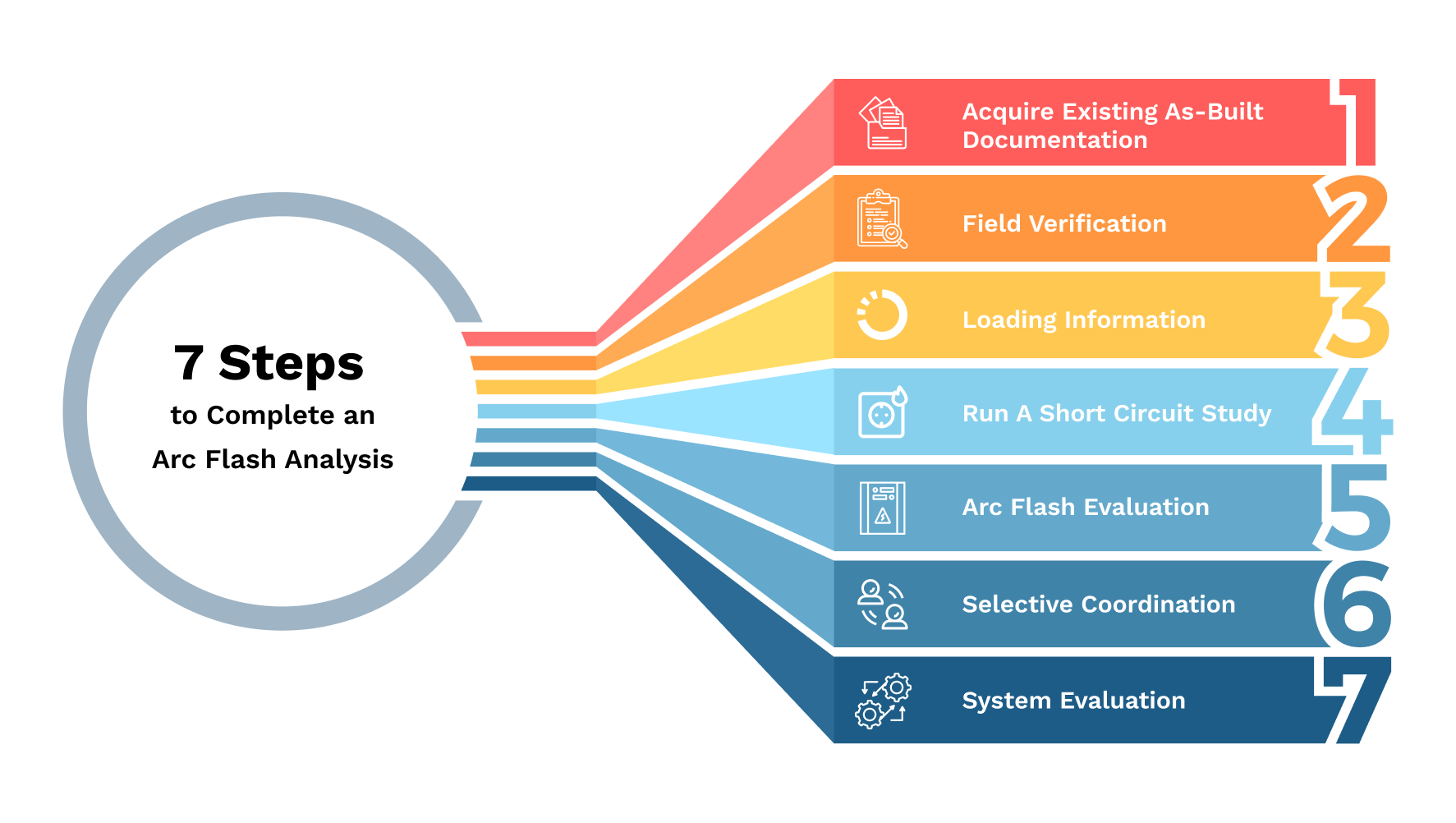

Acquire existing as-built documentation

Acquire existing as-built documentation

The usual starting point for an Arc Flash Analysis is to gather all of the existing electrical drawings that client may have. These would typically include:

If the documentation does not exist, electrical one-lines have to be developed in the field requiring a detailed field survey.

The electrical one-line diagram is the facility electrical distribution road map and is a key part of an Arc Flash Analysis.

Field verification

Field verification

Before entering the data from the electrical drawings into the Arc Flash Analysis program, the drawings must be field checked. This necessitates a site assessment to validate one-line documentation and identify any missing information in order to build a accurate one line diagram.

Each component data will be acquired from site. For example, PD (protective device) manufacturer/types/sizes/settings, cable type/lengths, transformer impedance values, and KVA sizes. Some of the equipment types that are taken into account are shown below.

Loading Information

Loading Information

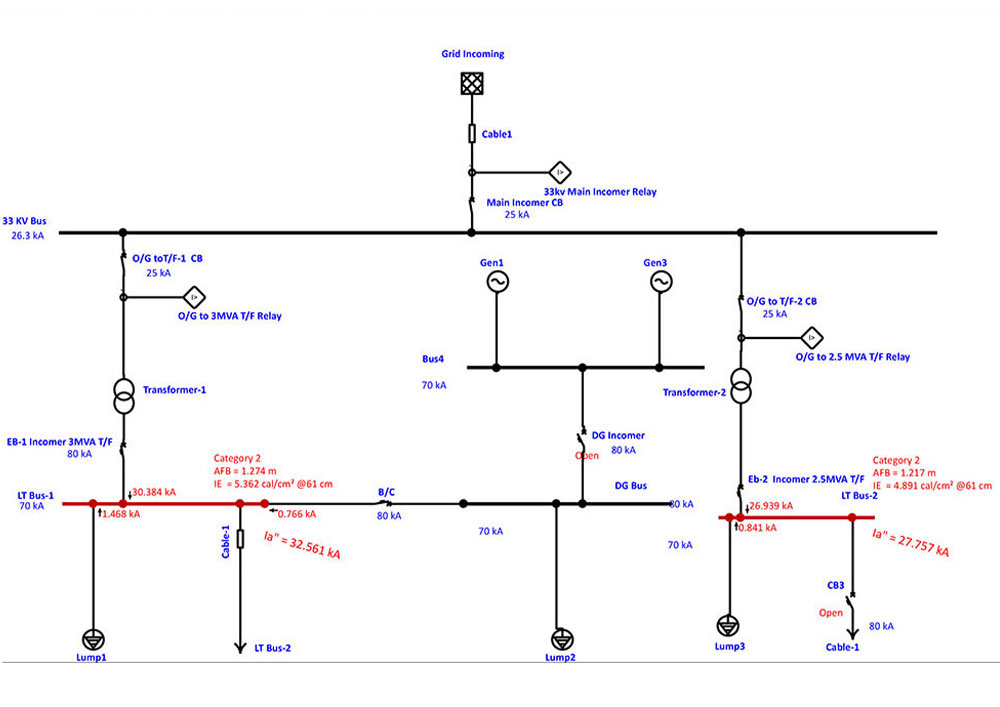

After the field survey is complete and the information on the drawings has been verified, this information is then loaded into power system software to run the Short Circuit, Coordination, and Arc Flash analysis.

This is how a one-line schematic loaded into the software will appear.

Run a Short Circuit Study

Run a Short Circuit Study

Once the data has been loaded into the power system analysis software, we review the 3 phase and single line to ground fault currents against the protective device “duty rating” to ensure the device can clear the fault. If a fault occurs at any given protective device, the value of the duty rating is the amount of fault current the device can handle and clear the fault in what we call a “bolted fault”. In other words, if the available fault current is less than the duty rating of the device, the device will do what it is intended and manufactured to do (clear it). If the fault currents are more than the duty rating, the device will likely fail and cause an arc flash incident.

Selective coordination

Selective coordination

The field data and power system analysis software are then used to conduct a coordinated research. In a well-coordinated system, the nearest protective device upstream of the fault will clear it without harming other protective devices farther upstream. This will limit the impact of a fault on the overall electrical distribution to the area in which it is located. To ensure that all over-current protection devices are coordinated, examine each device's time vs. current characteristics and compare them to those of any upstream devices.

Proper Coordination within a facility is of the utmost importance.

Arc Flash Evaluation

Arc Flash Evaluation

We assess the "as is" condition of the equipment under consideration in the study as a component of our report. We offer suggestions for reducing incident energy levels, including optimizing coordination, when applicable. For those protective equipments that support setting adjustments, it is possible to reduce "incident energy levels" and improve coordination. Coordination and arc discharge energy, also known as "incident energy," are undoubtedly interconnected. It is necessary to evaluate both in order to optimize the optimal settings for each. An instance of how results are obtained is provided below.

Analysis report and System Evaluation

Analysis report and System Evaluation

We will generate your Arc Flash Study Report after the calculations for the arc flash analysis program are completed. This will be handed to you for a brief review period, during which your team can assess changes. At this stage, we can hold a meeting to determine the report results. Following approval, we will give a final report along with the recommendations required. The digital version and physical version of the report and arc flash labels are also provided.

Completing the Arc Flash study includes:

Personnel Protective Equipment (PPE) includes clothing and equipment that provide full body protection in the event of an arc flash incident or electrical shock. The protection is based on the NFPA 70E guideline requirement of not receiving more than a second degree burn. A second degree burn is typically non-disabling and curable.

| Category | PPE | |

|---|---|---|

| Arc Clothing | Protective Equipment | |

| 1- 4 cal/cm2 | Arc-Rated Clothing, Minimum Arc Rating of 4 cal/cm2 (16.75 J/cm2) | Hard hat |

| Arc-rated long-sleeve shirt and pants or arc-rated coverall | Safety glasses or safety goggles (SR) | |

| Arc-rated face shieldb or arc flash suit hood | Hearing protection (ear canal inserts) | |

| Arc-rated jacket, parka, high-visibility apparel, rainwear, or hard hat liner (AN) | Heavy-duty leather gloves, arc-rated gloves, or rubber insulating gloves with protectors (SR) | |

| Leather footwear (AN) | ||

| 2- 8 cal/cm2 | Arc-Rated Clothing, Minimum Arc Rating of 8 cal/cm2 (33.5 J/cm2) | Hard hat |

| Arc-rated long-sleeve shirt and pants or arc-rated coverall | Safety glasses or safety goggles (SR) | |

| Arc-rated flash suit hood or arc-rated face shieldb and arc-rated balaclava | Hearing protection (ear canal inserts) | |

| Arc-rated jacket, parka, high-visibility apparel, rainwear, or hard hat liner (AN) | Heavy-duty leather gloves, arc-rated gloves, or rubber insulating gloves with protectors (SR) | |

| Leather footwear (AN) | ||

| 3-25 cal/cm2 | Arc-Rated Clothing Selected so That the System Arc Rating Meets the Required Minimum Arc Rating of 25 cal/cm2 (104.7 J/cm2) | Hard hat |

| Arc-rated long-sleeve shirt (AR) | Safety glasses or safety goggles (SR) | |

| Arc-rated pants (AR) | Hearing protection (ear canal inserts) | |

| Arc-rated coverall (AR) | Leather footwear | |

| Arc-rated arc flash suit jacket (AR) | ||

| Arc-rated arc flash suit pants (AR) | ||

| Arc-rated arc flash suit hood | ||

| Arc-rated gloves or rubber insulating gloves with protectors (SR) | ||

| Arc-rated jacket, parka, high-visibility apparel, rainwear, or hard hat liner (AN) | ||

| 4-40 cal/cm2 | Arc-Rated Clothing Selected so That the System Arc Rating Meets the Required Minimum Arc Rating of 40 cal/cm2 (167.5 J/cm2) | Hard hat |

| Arc-rated long-sleeve shirt (AR) | Safety glasses or safety goggles (SR) | |

| Arc-rated pants (AR) | Hearing protection (ear canal inserts) | |

| Arc-rated coverall (AR) | Leather footwear | |

| Arc-rated arc flash suit jacket (AR) | ||

| Arc-rated arc flash suit pants (AR) | ||

| Arc-rated arc flash suit hood | ||

| Arc-rated gloves or rubber insulating gloves with protectors (SR) | ||

| Arc-rated jacket, parka, high-visibility apparel, rainwear, or hard hat liner (AN) | ||

Benefits of employing

Benefits of employing