Applications

Applications

Our organisation categorises electrical components based on specific purposes and voltage criteria, simplifying their selection for diverse applications.

Earth Pit Testing

Earth Pit Testing

Earth pit testing, also known as ground resistance testing or earth resistance testing, is a crucial procedure in the electrical industry. It is performed to measure the effectiveness of the earth electrode or grounding system. This testing ensures that the grounding system provides a path of low resistance to the earth, which is essential for the safe operation of electrical systems and for protection against electrical faults. Here's a detailed overview:

Why is Testing Done?

Why is Testing Done?

To protect people from electric shock by ensuring that in the event of a fault, the electrical current has a low-resistance path to the earth, significantly reducing the risk of electric shock.

To prevent damage to electrical equipment by ensuring faults can be safely discharged to the earth.

To meet regulatory and safety standards which mandate a specific ground resistance value for different types of installations.

Why is it necessary?

Why is it necessary?

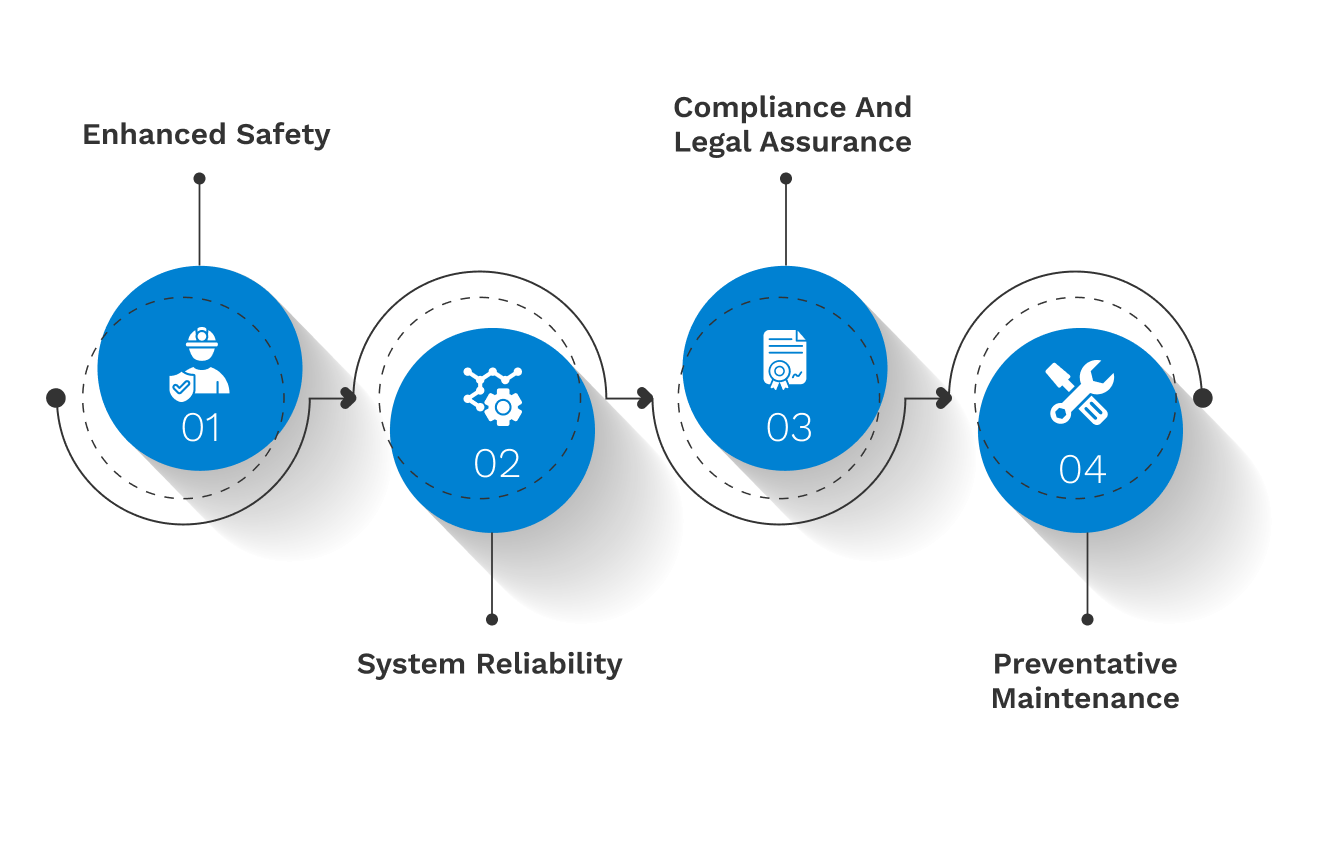

The necessity of earth pit testing in the electrical industry stems from several critical requirements and benefits associated with electrical safety, system performance, and regulatory compliance. Here’s a deeper look into why this testing is indispensable:

In essence, the necessity of earth pit testing is rooted in its role in safeguarding human life, ensuring the operational integrity of electrical systems, meeting legal and regulatory obligations, and adapting to environmental and site-specific factors. Regular and accurate testing of the earth pit or grounding system is thus a critical component of electrical safety and reliability protocols.

How is Testing Done?

How is Testing Done?

Testing is typically performed using one of the following methods:

This is the most widely used method. It involves using a ground resistance tester to measure the resistance between the earth electrode and two other points placed in the ground in a straight line at predetermined distances. This method provides a measurement of the earth electrode's resistance to ground.

Used when the installation is not energized, comparing the resistance with a known good earth connection.

This method uses a clamp-on meter to measure the ground resistance without needing to disconnect the ground system. It's useful for measuring the resistance of multiple grounding paths simultaneously.

This method isolates and tests individual grounding electrodes without disconnecting them from the grounding system, using a selective ground resistance tester.

Key Points to Remember

Key Points to Remember

In summary, earth pit testing is an essential procedure in the electrical industry for ensuring safety, compliance, and the reliability of electrical systems. It involves specific techniques and equipment to measure the effectiveness of the grounding system, with significant benefits for both safety and operational efficiency.

Benefits of the Testing

Benefits of the Testing